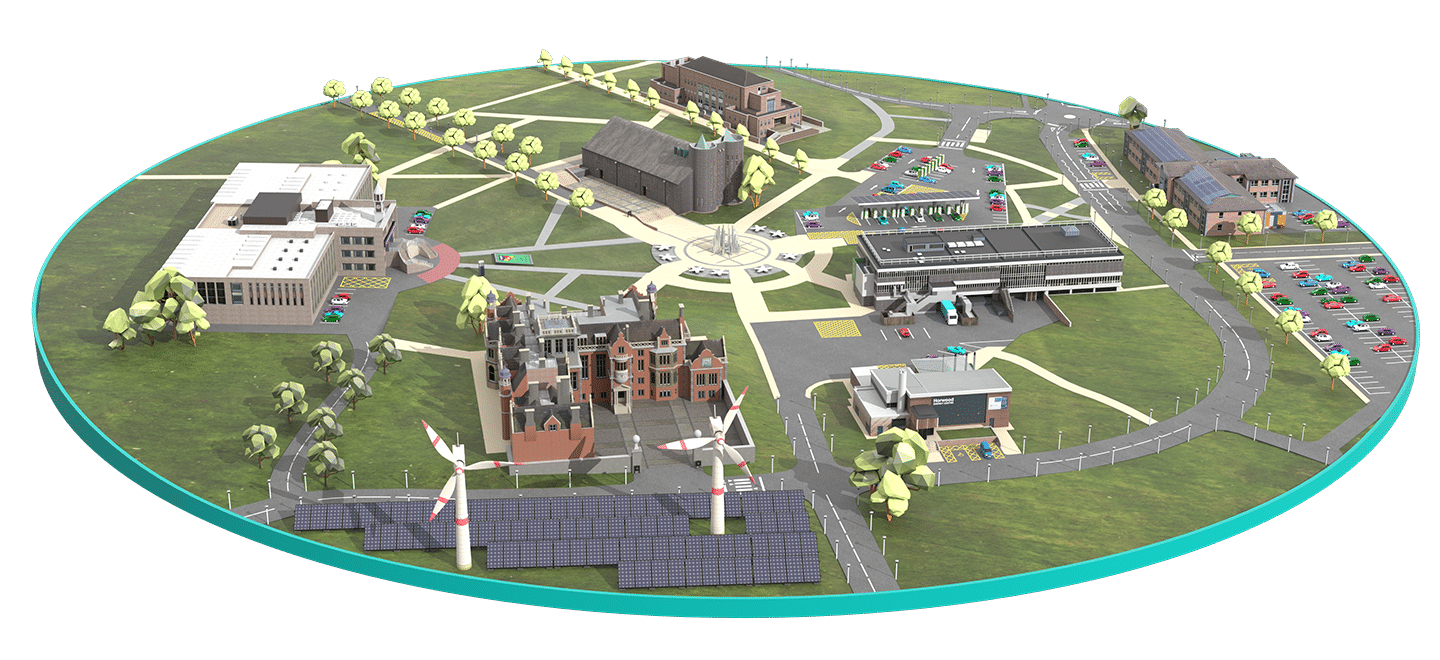

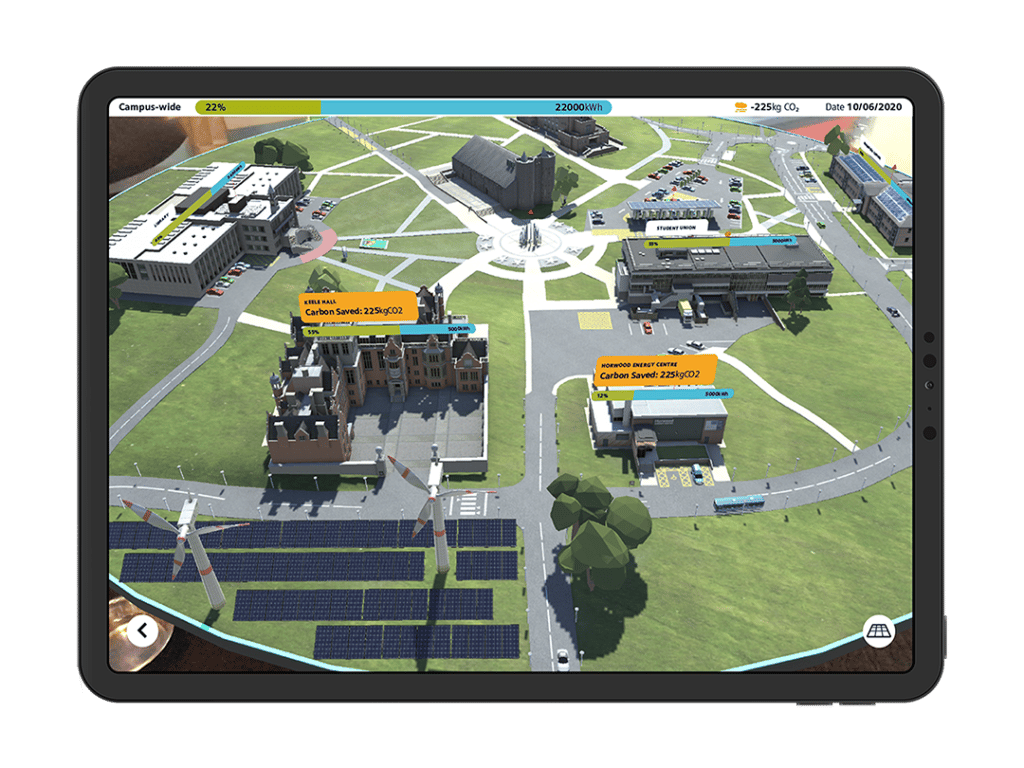

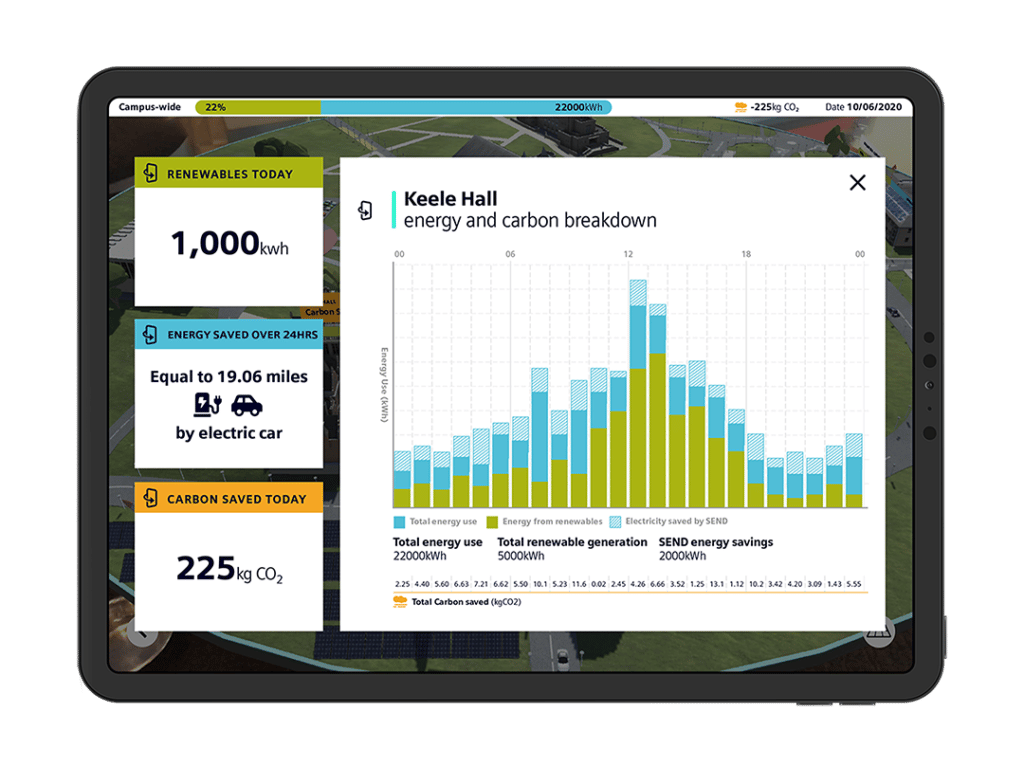

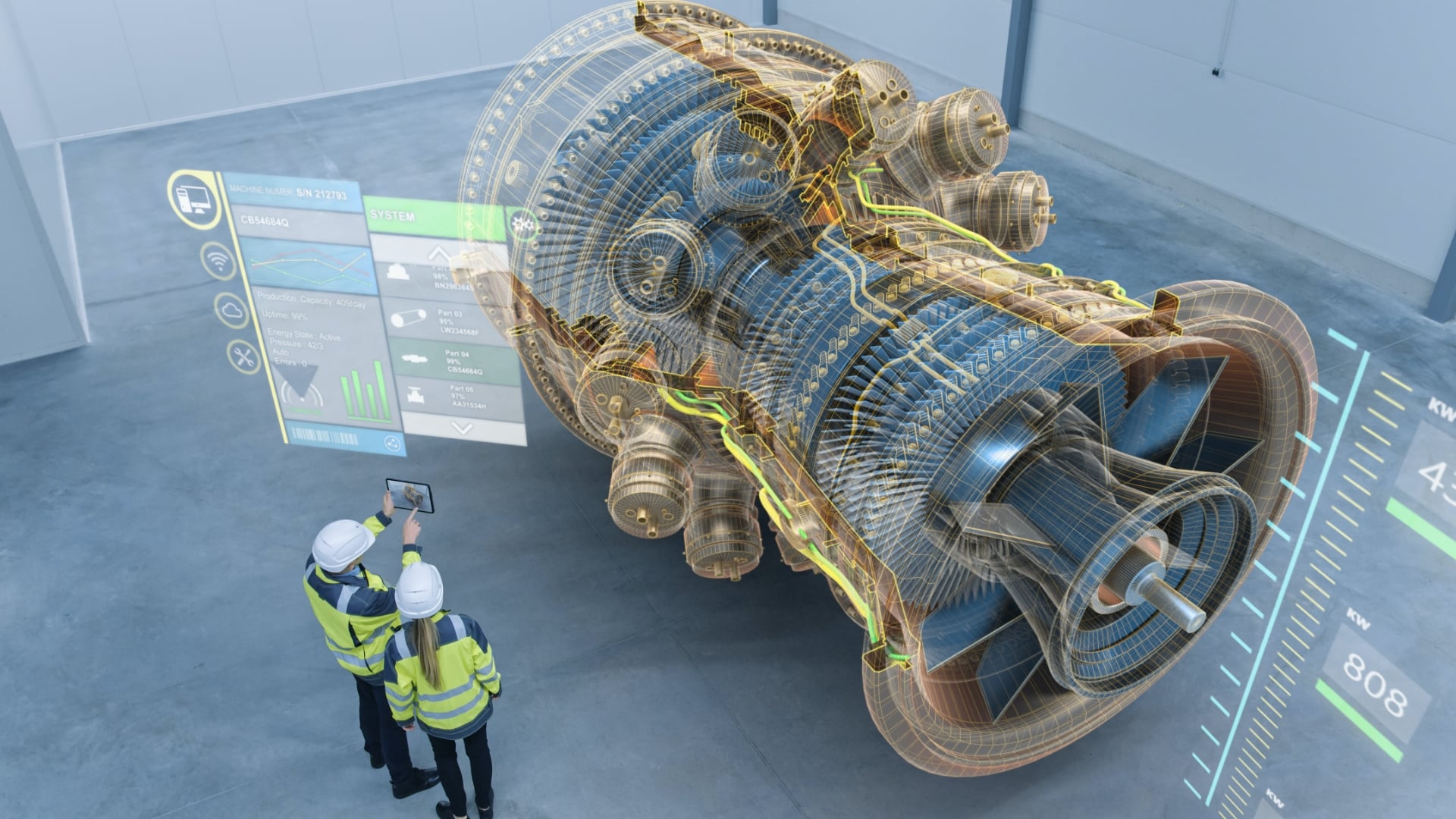

A digital twin is a virtual replica of a physical object, process or space. Sensors on the original feed functionality data into the digital twin, including factors like energy use or output, temperature, efficiency, weather conditions, frequency of use and more. This data can be used to simulate the object, process or space on the digital version helping study performance and simulate potential improvements.

Digital twins are the multi-industry superstars of the immersive revolution – used in the manufacturing, engineering, architecture and planning, energy, and healthcare sectors and are key to plans for net zero.

Digital twins and data-led industry practices increase site performance by 17-20%

It used to be the case that iteration, testing and improvement of processes was a costly, potentially damaging on-the-ground process. With digital twins you can remove the guesswork and get closer to real-world solutions before costly deployment by visualising in 3D and in real time.

Digital twins are a powerhouse, bridging the gap between the real world and all kinds of key data. Using digital twins helps visualise data effectively and intuitively, allowing new ideas to come to the fore and be tested safely and securely before being deployed in the real world.